Lexus should think long and hard about changing its tagline to “way of the future” thanks to all of its recent designs and gadgets. After succumbing to Back to the Future II fever with its brand-new fandangled hoverboards, this week, the luxury car company unveiled the Origami Car—a real, working automobile that is made almost entirely out of cardboard and held together with wood glue.

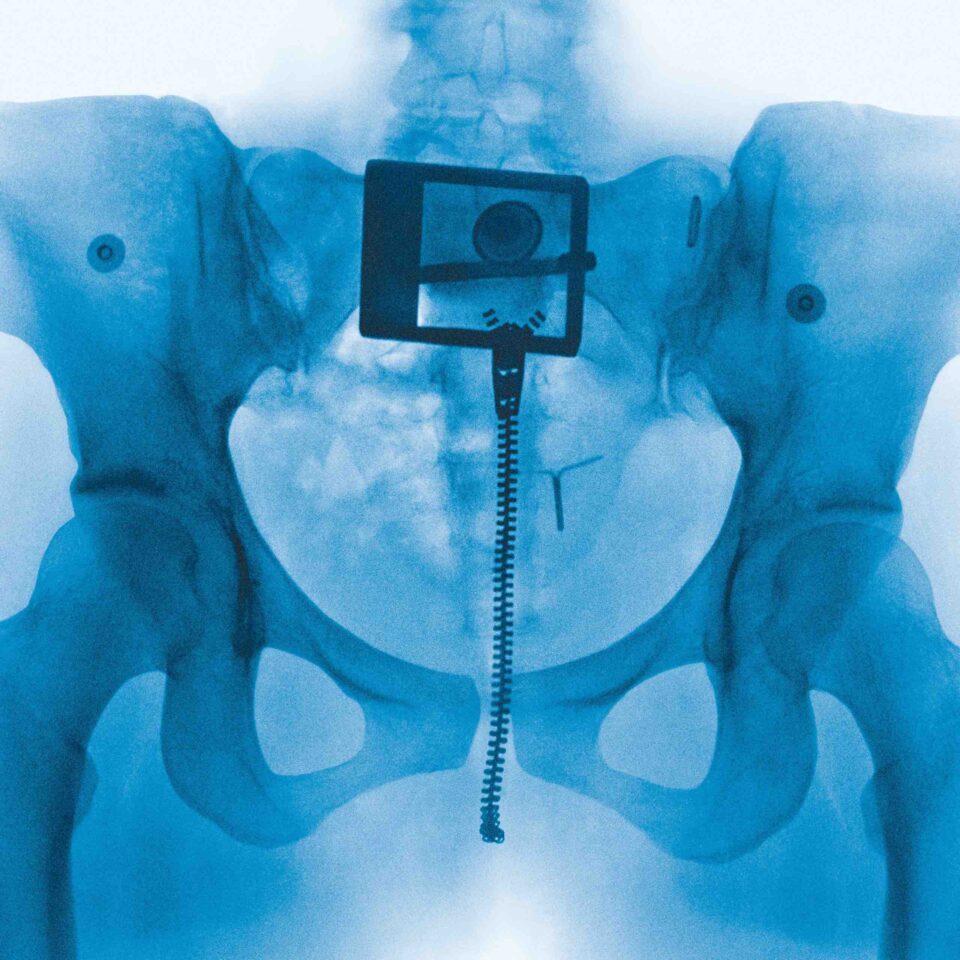

Premiering at the Grand Designs Live Show in Birmingham, England, the Origami Car is a fully functional car that’s only non-cardboard pieces are the electric engine with its steel/aluminium frame, and the headlights. Everything else is made of laser-cut pieces of recyclable cardboard, including the wheels, the seats, and the entire exterior.

The experiment-turned-marketing-tool-turned-art-project was built by an insanely dedicated team of five London designers and engineers from LaserCut Works and Scales and Models who took the insanity of building a cardboard luxury car in stride: “The seats took a few attempts to get just right and the wheels required a lot of refining. Once we could see the physical pieces taking shape, we could identify where we needed to make improvements – as with anything, there were some elements of trial and error, but as we had all the resources we needed in-house, this made the changes easier to produce.”

Read about the painstaking process and watch a behind-the-scenes video below:

Lexus provided the team with a digital 3D model of the IS, which was then divided into a series of principal parts, such as the main body, dashboard, seats and wheels. These were then digitally rendered in 10mm “slices” to provide the two-dimensional profiles needed for the laser cutting of each of the 1,700 sheets of 10mm-thick of cardboard – supplied by packaging experts DS Smith. Each layer was given its own reference number to help ensure it was assembled in the right sequence and the entire assembly was done by hand. A water-based/wood glue was used, which had to be left to set for 10 minutes after each application. Accuracy was vital, as changes couldn’t be made once the glue had dried. In all, the Origami Car took three months to build.

(via Huffington Post)